How to

How to Replace John Deere engines Connecting Rod Bushing

How to Replace John Deere engines Connecting Rod Bushing

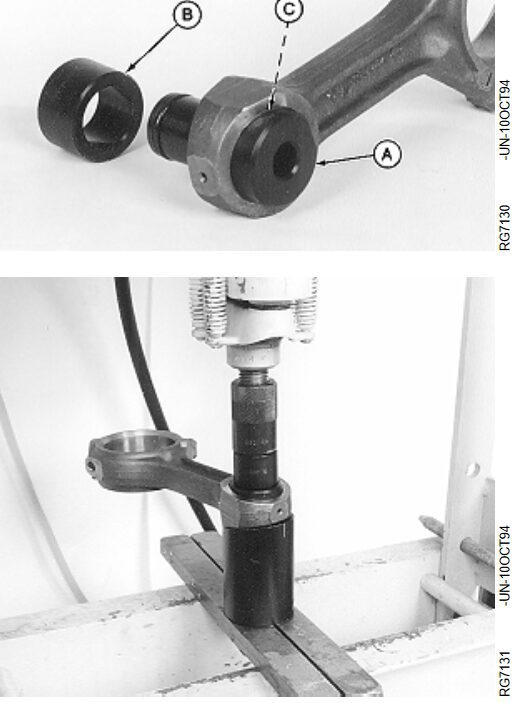

Using JDG738 Connecting Rod Bushing Service Set, proceed as follows.

1. Slide driver JDG738-1 (A) into one side of rod bushing (C). Turn the driver until the taper on the driver flange

matches up with the taper on the bushing.

2. Install receiver cup JDG738-3 onto the opposite side of the rod bushing.

NOTE: Stud in cup keeps rod properly located on the cup. Use JDG738-2 pilot ring (B) as a hollow spacer when pressing the bushing out of the rod.

3. Using a hydraulic press, push the bushing out of the rod until the driver and bushing fall into the receiver cup

4. Slide bushing (A) onto JDG738-1 driver (B) and install JDG738-2 pilot ring (C) onto the O-ring end of the driver.

5. Apply TY6333 grease* to:

- Outside diameter of the bushing

- Outside diameter of the pilot ring

- Inside diameter of the rod pin bore

6. Insert the driver into the rod pin bore so the pilot ring pilots in the rod bore and bushing taper aligns with a taper on the driver flange. Align the oil hole in bushing (D) with the oil hole in the end

of the rod (E).

7. Install the JDG738-3 receiver cup (F) onto the opposite side of the rod so the taper-on rod aligns with the taper-on receiver cup.

8. Press the bushing into the rod until the edge of the bushing is the flush machined surface on connecting rod face.

IMPORTANT: Oil holes MUST be aligned. If holes are not aligned, remove and discard the bushing then re-install a NEW bushing.

DO NOT attempt to reuse a bushing.

9. Have the new bushing reamed by a specialized workshop to obtain an oil clearance of 0.020 to 0.056

mm (0.0008 to 0.002 in.) with piston pin.