How to

How to Update a JCB Backhoe Loader Wear Pads

How to Update a JCB Backhoe Loader Wear Pads

JCB Backhoe Loader 3CX, 4CX, 214e, 214, 215 217Power Sideshift ®C Wear Pad Renewal Inspection (1000 hours)

When the wear pads are worn to 6 mm (0.23 in) or below they should be replaced.

It is permissible to rotate the top wear pads 180°„ to prolong service life, provided the contact surface is more than 6 mm (0.23 in) thick.

Note: If rotating the wear pad the grease nipples will have to be swopped over.

JCB Heavy Duty Truck Diagnostic TOOL JCB Electronic Service tool with JCB Service Master 4 V22.4.2

- Park the machine on the firm-level ground, engage the parking brake, and set the transmission to neutral. Lower the loader arms to the ground.

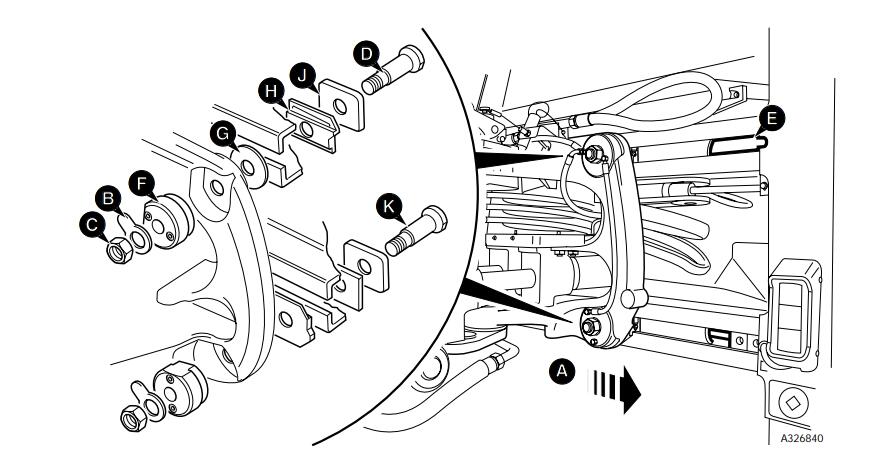

- Set the carriage fully to the end of travel A, shown in the center position for clarity.

- Lower the bucket to take the weight off the kingpost.

- Switch OFF the engine and remove the starter key, and operate the control levers to vent residual hydraulic pressure.

- Unlock the top lock tab B and unscrew nut C.

- Remove bolt D through the slot in rail E.

- Hydraulic clamp F and washer G should remain in position.

- JCB ServiceMaster4 V23.2.1(02.2023) Diagnostic Software Download and installation

Remove plate J and wear pad H. Assembly - Fit wear pad H, plate J, and bolt D.

- ?Fit new lock tab B and fit nut C.

- ?Set the hydra clamp clearance as described in Sideshift ®C Hydraclamp Clearance Setting.

- Repeat procedure steps 5 to 11 for the bottom clamp. The only difference on the bottom clamps is the wear pad is on the opposite side of the rail from the top clamp so bolt K need not be completely removed.

- Note: If the wear pad is trapped between the rail and carriage, lower the bucket to relieve the load on the wear pad.

- Lift the bucket and set the carriage to the opposite end of the travel, repeat the procedure for the opposite side.

- When all clamps have been assembled recheck the hydra clamp clearance of all clamps

- JCB ServiceMaster 4 Free Download for Win 7Win 8Win 10