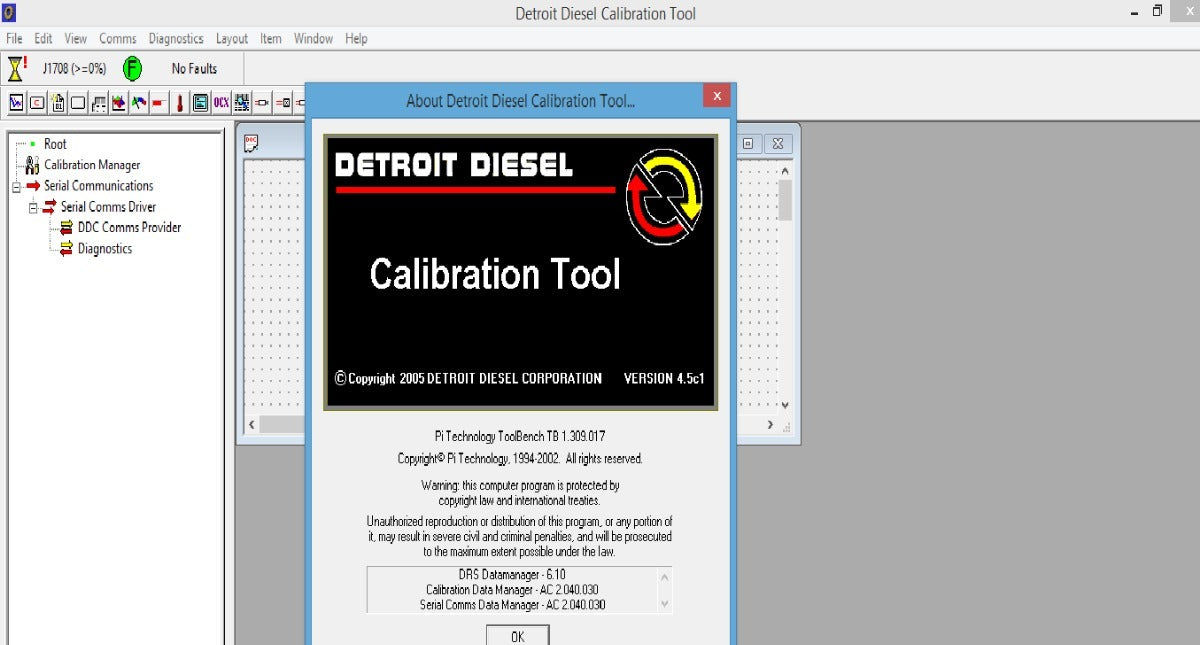

Detroit Diesel Calibration Tool (DDCT) v4.5 English Include Calibrations Metafiles

$200.00

Detroit Diesel Calibration Tool (DDCT)

v4.5 English Include Calibrations Metafiles

1 in stock

Detroit Diesel Calibration Tool (DDCT) v4.5 English Include Calibrations & Metafiles

The DDCT Cal Tool provides a programmable software interface to the Electronic Control Module (ECM) in an engine.

Using the DDCT Cal Tool, you can:

°§ View and edit the control parameters in the ECM to optimize the control logic

°§ View instrumentation variables, such as rpm or fluid temperatures and pressures, while the engine is running.

The control parameters and variables can be of many different types (such as integers, floating points, or enumerated values) and structures (such as single-valued scalars or one, two, or three-dimensional tables).

The DDCT Cal Tool provides a wide range of controls for viewing and editing all these types of values, including:

°§ Virtual instruments such as analog meters, thermometers, bars, and sliders.

°§ Table graphs.

°§ Buttons.

°§ Text and Table Editor Controls.

The control parameters for an ECM are defined in two files: a metafile (.MET), which can be created using Pi’s Metafile Compiler, which defines the structure; and a Calibration file (.CAL) generated by the DDC Cal Tool, which contains the parameter values.

Calibrations can be edited off-line or online:

To edit a Calibration off-line, you can either:

(a) Open a file containing a saved version of the Calibration, or

(b) Connect to the ECM, read the Calibration, and then disconnect.

You can then edit the Calibration in the DDC Cal Tool and either save the edited version to download to the Calibration at a later time, or connect to the ECM and download the Calibration to the ECM immediately.

°§ To edit parameters online, you identify the parameters to be edited and then set them to °ÆCal on the Fly’ mode – the DDC Cal Tool first uploads the current values of the Cal on the Fly parameters from the ECM, then, until you leave Cal-on-the-fly mode, any changes you make to those parameters in the DDC Cal Tool are sent immediately to the ECM while it is running.

Typical applications for the DDC Cal Tool include:

°§ debugging new ECM control logic;

°§ optimizing operation by fine-tuning individual control parameters for a device while it is running;

°§ reprogramming an ECM to accommodate changing requirements.

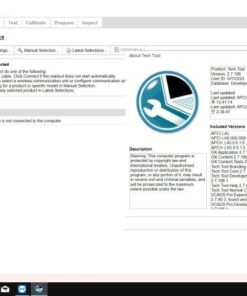

We Are Offering Full Teamview Support,

We will Connect To your Pc.

And Install The Software For you !!

Product Details :

– O.S.: Windows XP; Windows Vista; Windows 7; Windows 8

– CPU: Pentium/Athlon 2.0 GHz or higher

– RAM: 1 GB of system memory

– Hard Drive: 5 GB of available space

Related products

Trucks Diagnostics